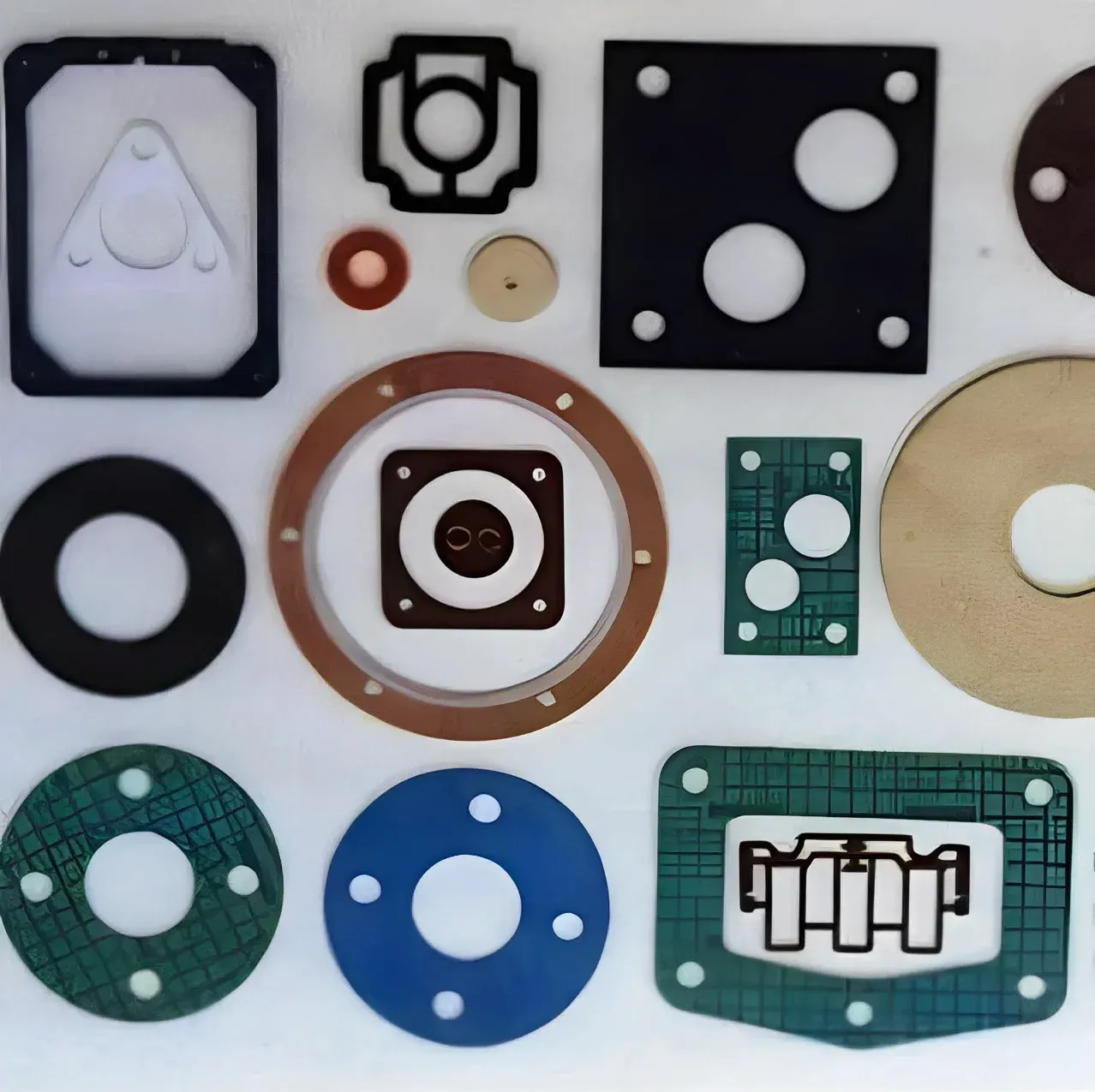

Asbestos-free cut gaskets in Milan

To achieve a flawless result, the material from which the gaskets are made must be sufficiently compressible during assembly of the parts, so that, once applied, it can easily fill all the spaces, including the slightest irregularities.

The greatest strength of these gaskets lies in their ability to withstand high compressive loads, as pressures of up to 14 MPa can be reached in industrial applications. Contact IMGT, a company that for over fifty years has provided customers with specific and exclusive expertise to create customized solutions at competitive prices.

Die-cut gaskets

- Asbestos-free

- Neoprene®

- Canvas rubber

- Expanded rubber.

- Silicone

- Vulkollan®, Adiprene®

- Felt

- Graphite

- Polythene, Nylon

- Cork

PTFE gaskets

Seals applicable to any surface

The material chosen to make the gasket must satisfy some essential characteristics:

• It must be soft enough to adapt to surfaces.

• It must not be chemically attacked by the fluid it contains.

• It must not attack the surfaces with which it comes into contact.

• It must withstand the operating temperature, whether high or low.

• It must resist the pressure of the fluid to be contained without deforming.

When used in dynamic seals, they must produce little friction and wear as little as possible. Gaskets are used to connect mechanical parts that do not fit perfectly.

The gasket can:

• compensate for irregularities in the support area due to the production process

• compensate for flatness defects on large surfaces

• prevent a reduction in hold over time

• widen the contact surface between the two elements. If the gasket is sufficiently compressible, or if its thickness can be adjusted, it can provide a calibration space for the fixing distance of the two elements.

This is very important for reciprocating internal combustion engines, giving the possibility to precisely adjust the coupling of for example (cylinder/crankcase or cylinder head/cylinder).

• DIE-CUT SEALS - Asbestos-free - Neoprene® - Dutral® - Canvas rubber - Expanded rubber - Silicone - Vulkollan®, Adiprene® - Felt - Graphite - Polythene, Nylon - Cork; PTFE SEALS

State-of-the-art machinery

IMGT has a state-of-the-art fleet of machinery, capable of performing precision work efficiently and punctually. Both injection and compression molding machines are used to mold any elastomeric material.

Our gaskets are produced by cutting sheets of material such as:

• Paper • Rubber • Silicone • Cork • Metal • Felt • Neoprene • Fiberglass • Plastic containing asbestos fibers.

To ensure the hermetic integrity of threaded joints and fittings, such as in hydraulic pipes, two materials are mainly used:

• Teflon, in the form of a tape

• hemp fibre, (also called tow) combined with a graphite-based lubricating paste (green paste) in our case they are made of - Neoprene® - Dutral® - Canvas rubber - Expanded rubber - Silicone - Vulkollan®, Adiprene® - Felt - Graphite - Polythene, Nylon - Cork.

Request a quote

Fill out the form and our team

will contact you as soon as possible.