IMGT Milan

International

Gaskets Manufacturing

Technological

IMGT was founded in 1967 as a small-scale company specializing in the production of technical articles, rubber gaskets, asbestos-free materials, and plastics. Thanks to the tenacity, determination, and strategic vision of its founders, the company has experienced steady growth over the years, developing advanced organizational capabilities and remarkable operational flexibility.

This approach has allowed it to respond effectively and precisely to the needs of an increasingly attentive, demanding, and quality-oriented clientele.

IMGT operates in international markets such as Europe, the United States, India, and China, with the aim of further expanding its presence.

IMGT Srl is a family-run business founded and owned by the Bozzini family. Our story begins in the 1960s in Milan, when brothers Giuseppe and Francesco started a small company specializing in the production of technical gaskets. Thanks to their experience and expertise, IMGT is now a successful medium-sized manufacturing company.

The company is currently managed by the next generation of the Bozzini family: Gianluca serves as General Manager, while Cristian is Production Director. Together with a team of 20 employees, they form the beating heart of IMGT. The company is organized into six main departments: Administration and Finance, Purchasing, Sales, Production, Quality, and Logistics, all interconnected to ensure efficiency, quality, and customer satisfaction.

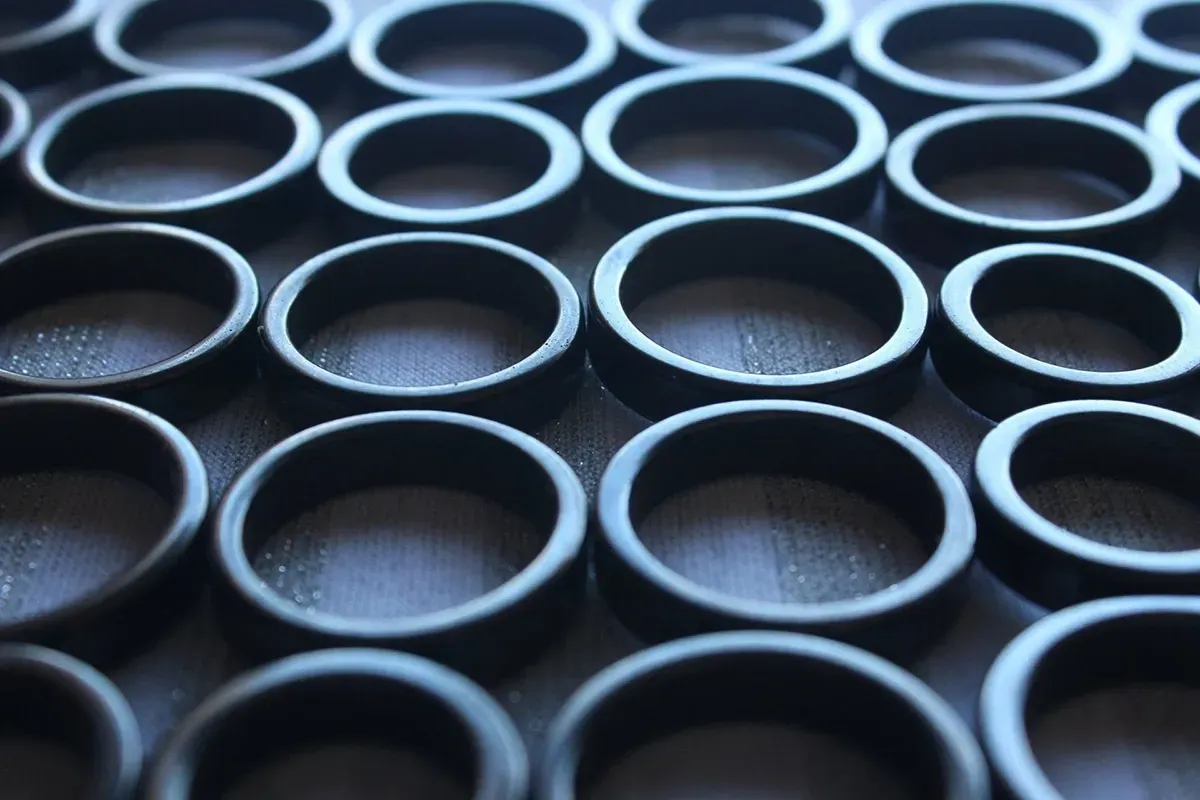

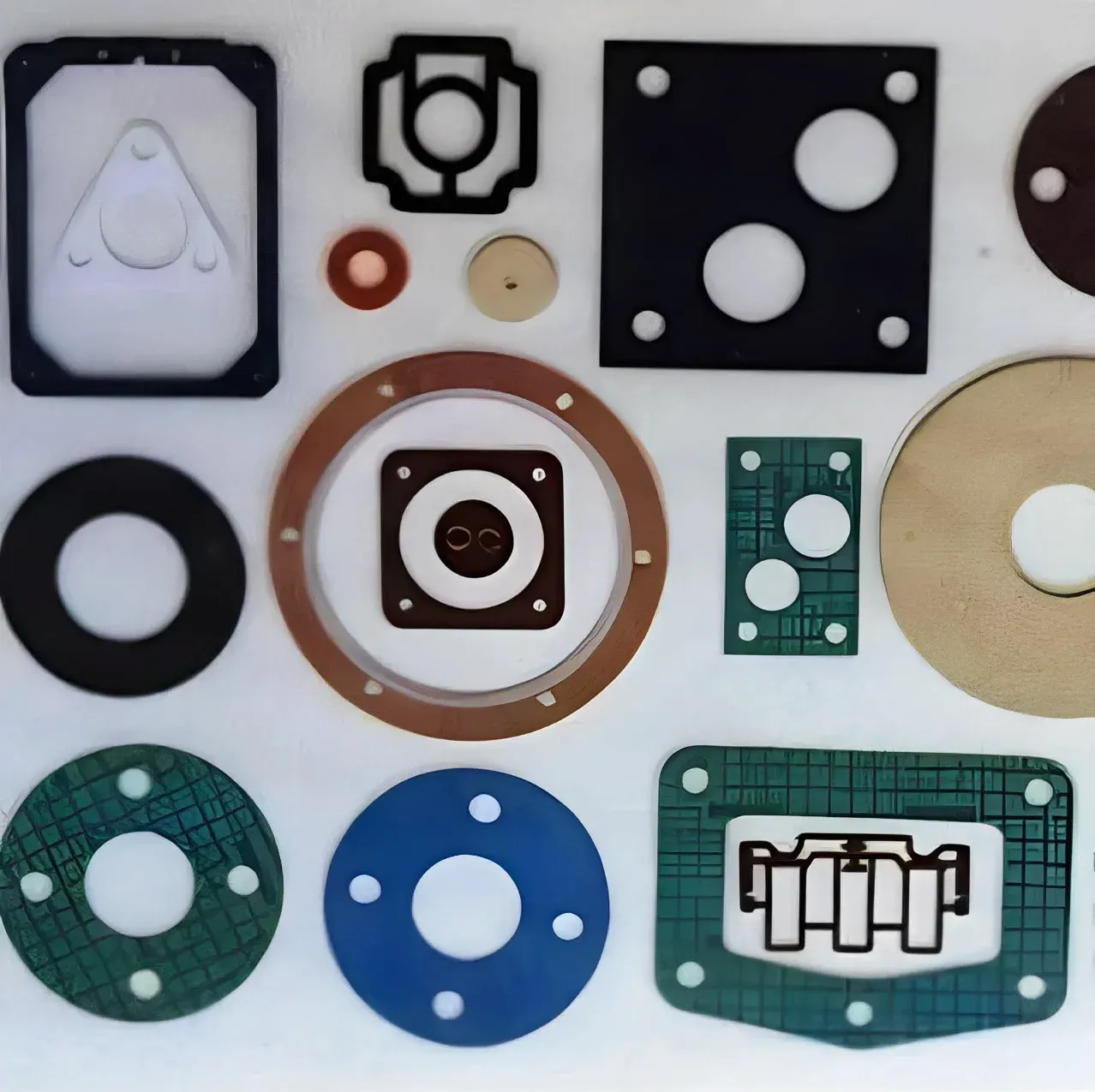

Production of technical gaskets

Our core business is the production of technical gaskets, made from a wide range of materials, including elastomers (NR, SBR, NBR, HNBR, CR, EPDM, VMQ, FVMQ, FKM), thermoplastics (PTFE, PA, PVC, PP), asbestos-free materials, graphite, and felt.

All raw materials used are top-quality and certified by internationally accredited laboratories. To meet our customers' needs, elastomeric compounds for food contact can be specifically formulated and certified in compliance with national and international regulations (FDA, 3A Sanitary, WRAS, UBA). Furthermore, raw materials are carefully inspected upon arrival to ensure high quality standards. Our procurement policy prioritizes materials produced in Italy, carefully selecting suppliers.

Production techniques

The production techniques used in our factory include:

- Molding (injection and compression)

- Extrusion

- Shearing

- Waterjet cutting

- Pantograph cutting

- Turning

This versatility allows us to produce small, medium, and large-scale production runs, both for standard gaskets and for customized products tailored to specific customer requests.

Application sectors

Our products find application in various sectors, including:

- Oil & Gas

- Petrochemical

- Naval

- Medical and Pharmaceutical

- Veterinarian

- Food industry

- Water sector

- Heat transfer

- Construction and Electrical Industry

- Home appliances

- Automotive sector

Conformità alle normative

We produce articles compliant with

Italian and European Laws and Regulations on materials and objects suitable for contact with food (MOCA), as required by EC Regulation 1935/2004, EC Regulation 10/2011, EC Regulation 2023/2006 and Ministerial Decree 21.03.1973. Each production is traceable thanks to the assignment of a specific batch.

ISO 9001 Certification

The company is certified ISO 9001, demonstrating our ongoing commitment to quality management and continuous improvement of our production processes. This certification ensures that all stages of production, from raw material selection to the finished product, follow rigorous standards to ensure reliability, safety, and compliance with current regulations.

WORK IN PROGRESS

ISO 14001 Certification

We look at the environment with respect

100% Green Energy

We have always invested in innovation and corporate improvement with a strong commitment to sustainability. Our factories use 100% energy Renewable thanks to photovoltaic systems, we reduce consumption with LED lighting and limit the use of plastic and packaging for a lower environmental impact.

IMGT believes in a sustainable future and continues to develop eco-friendly solutions to respect the environment and future generations.